Control PWM fan using PID and temp sensors with Arduino

Objectives

In this post I explain how to realize a self regulating fan cooling system using Arduino.

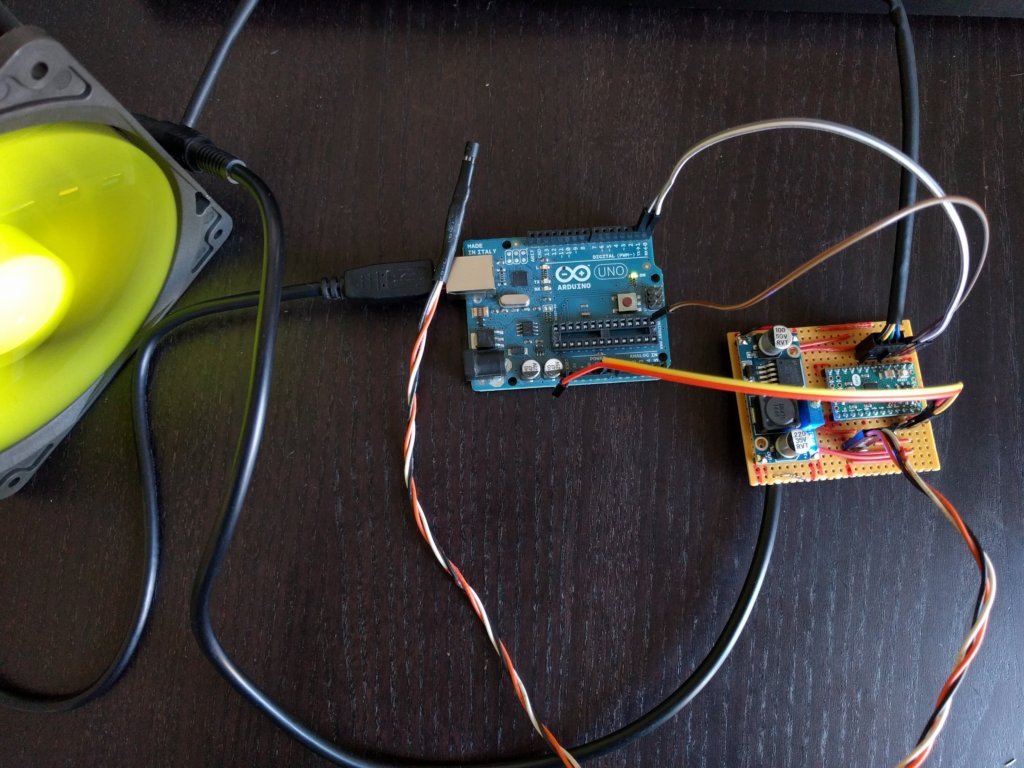

In my case I wanted to cool a custom NAS placed in a closet, using two fans (in and out).

I also wanted to act on the difference between internal and external temperature. Indeed, it’s a nonsense to set a 25° temperature when outside it’s 30°.

PID Control

PID (Proportional Integral Derivative) is a common way to regulate a system, widely used in industry.

A PID controller continuously delivers a command signal to reach a fixed setpoint. Measurements allows to calculate an error to adjust the command signal.

Learn more about PID (wikipedia).

In this project I’m using this great PID library.

It’s really simple to setup, but, as said everywhere : the real tricky part is to set kp, ki and kd, according your needs and configuration.

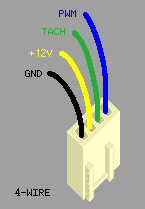

PWM Fan

PWM (Pulse Width Modulation) fans are very common, and could be found in computers, networks components…

This fans are modulated using PWM and could be monitored through a tachymeter output.

In my case, I’ve bought Coolink SWiF2-120P, capable of a 36CFM@12v, that could be found here on amazon

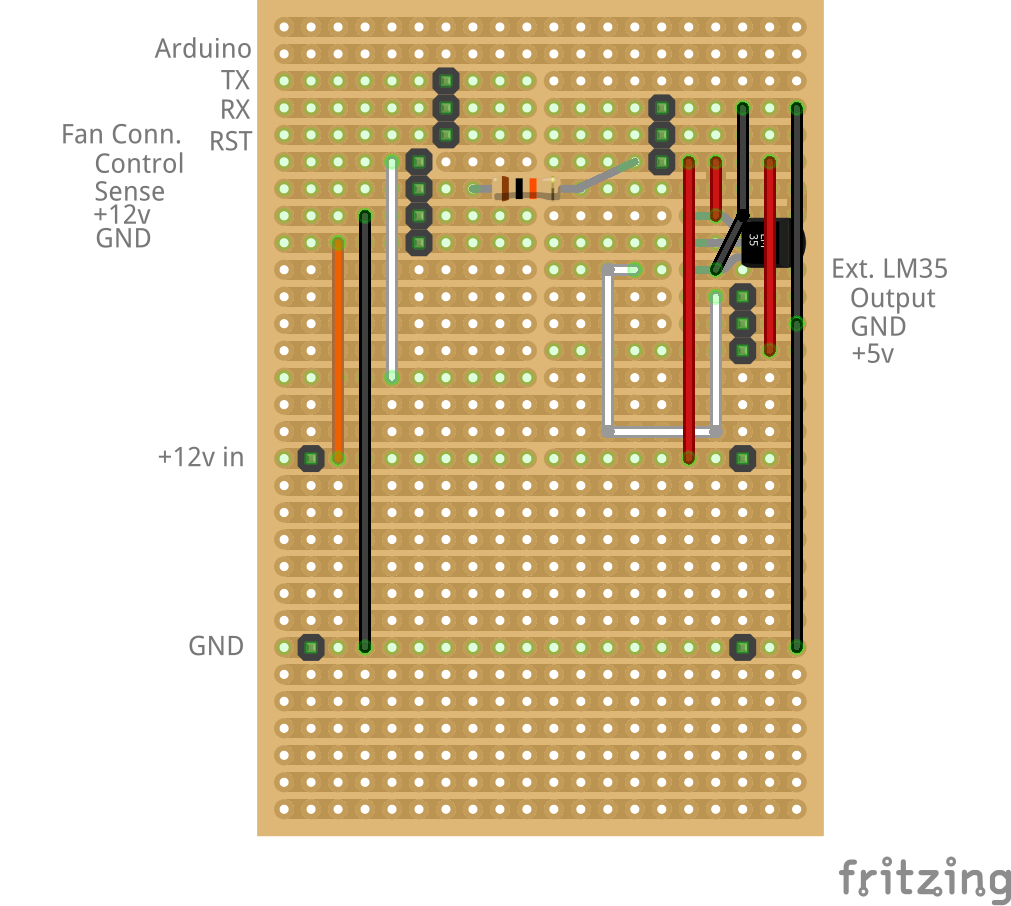

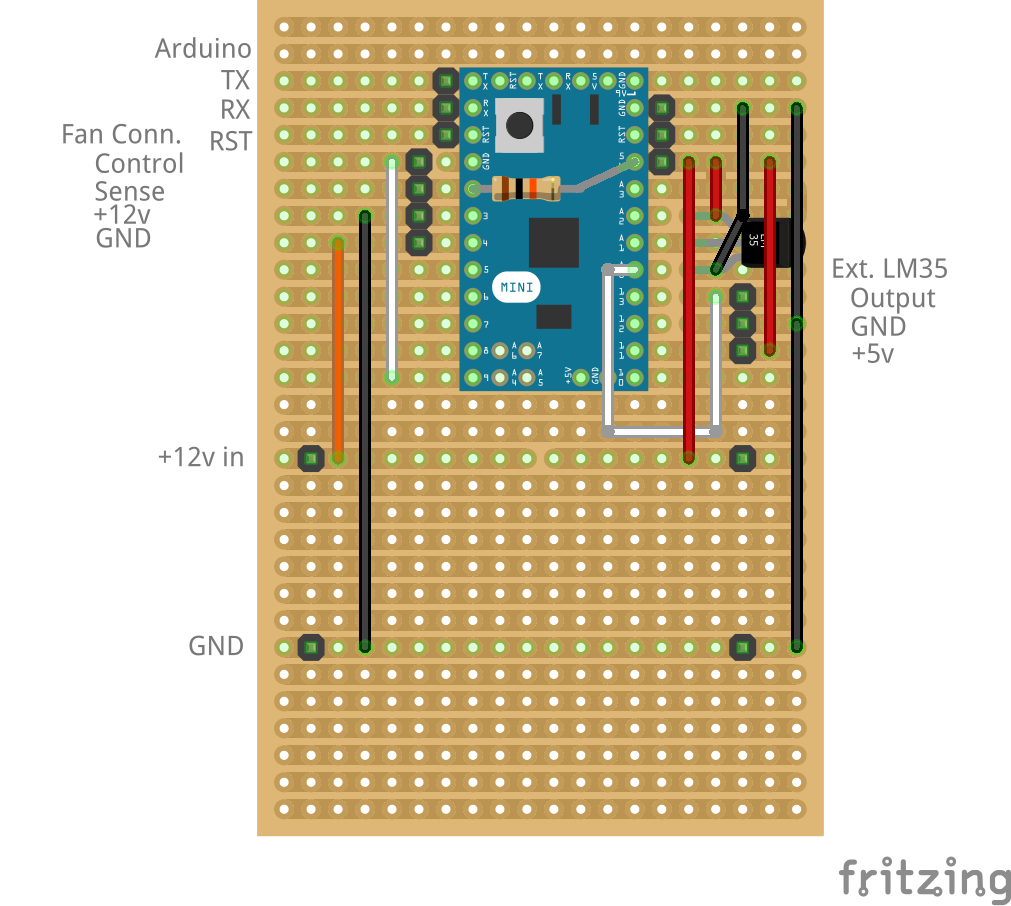

Electronic setup

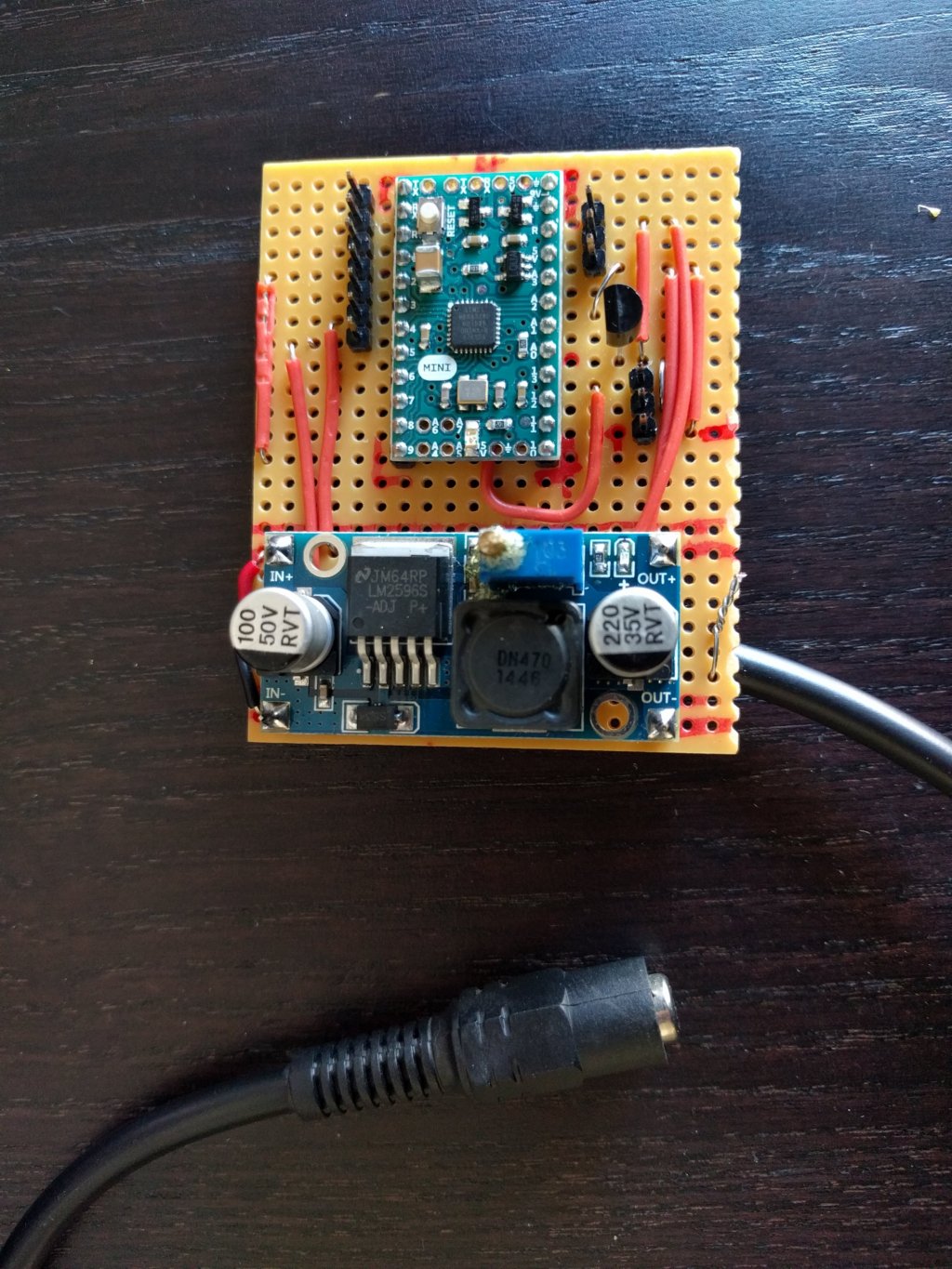

Arduino

I’ve chose Arduino Mini for this project, but it could be exhanged by most of standard Arduino boards.

Arduino Mini is very compact, but has no USB interface. You’ll need an external programming board, such as another (regular) Arduino board.

There’s a lot of resources to learn doing this, an example here.

Power

Fans are powered with +12v source. I’ve planned to power Arduino Mini using the same power adapter, with a voltage regulator.

I’ve chose a LM2596 DC to DC, which could be found on amazon here.

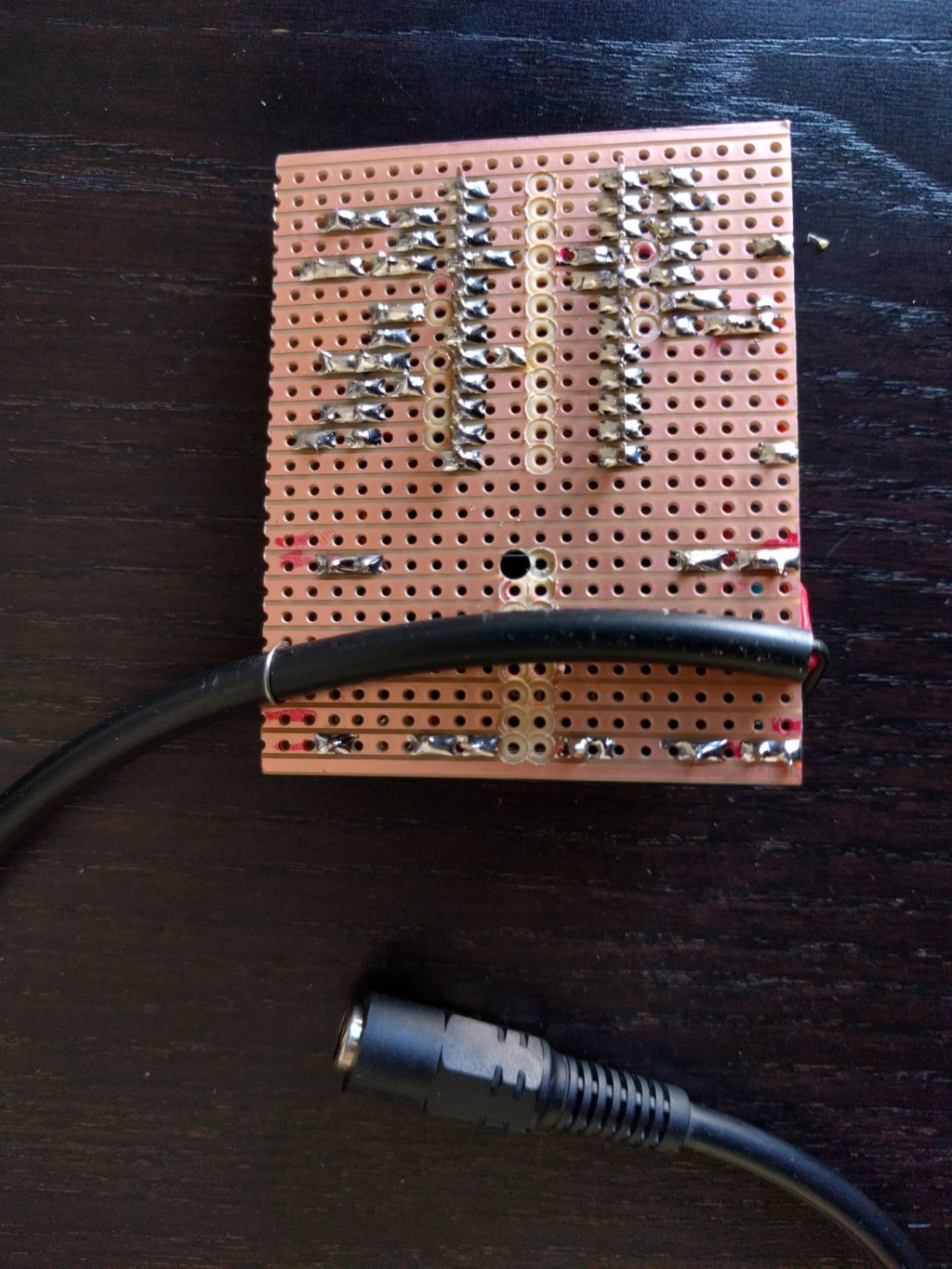

Temperature sensors

I’m using two standard LM35 temperature sensor. There’s a lot of resource about using it easily with Arduino, as in this Arduino Playground article.

One sensor is directly sold on the board for internal measure, the other is attached to a cable for external measurement.

Software

Arduino code

#include <PID_v1.h>

int fanPulse = 2; //tachymeter fan pin

int fanControl = 9; //pwn fan pin

int pinTempInt = 1; //internal temp sensor pin

int pinTempExt = 0; //external temp sensor pin

int avgLoop = 5; //temp measurement loops

//PID parameters. I'm using defaults with quite nice results

double kp=2; //proportional parameter

double ki=5; //integral parameter

double kd=1; //derivative parameter

//Setpoint (Maximum difference between internal and external temperature)

double maxTdiff = 5;

//Minimum and Maximum PWM command, according fan specs and noise level required

double commandMin = 0;

double commandMax = 250;

double tempInt, tempExt, tempDiff, command;

unsigned long pulseDuration;

//init PID

PID myPID(&tempDiff, &command, &maxTdiff,kp,ki,kd, REVERSE);

boolean first = true;

void setup()

{

Serial.begin(9600);

pinMode(fanPulse, INPUT);

digitalWrite(fanPulse,HIGH);

pinMode(fanControl, OUTPUT);

tempInt = getTempInt();

tempExt = getTempExt();

tempDiff = tempInt - tempExt;

if(tempDiff < 0) {

tempDiff = 0;

}

//turn the PID on

myPID.SetMode(AUTOMATIC);

myPID.SetOutputLimits(commandMin, commandMax);

}

//internal temp

double getTempInt() {

return getTemp(pinTempInt);

}

//external temp

double getTempExt() {

return getTemp(pinTempExt);

}

//get temp of pin sensor

double getTemp(int pin) {

double rawTemp;

rawTemp = analogRead(pin);

double temp = rawTemp * (5.0 / 1023.0 * 100.0);

return temp;

}

//get current fan speed

double getFanSpeed() {

pulseDuration = pulseIn(fanPulse, LOW);

double frequency = 1000000/pulseDuration;

return frequency / 4 *60;

}

//print log firstline

void header() {

Serial.println("PID Setup");

Serial.print("kp [");

Serial.print(kp);

Serial.println("]");

Serial.print("ki [");

Serial.print(ki);

Serial.println("]");

Serial.print("kd [");

Serial.print(kd);

Serial.println("]");

Serial.print("maxTdiff [");

Serial.print(maxTdiff);

Serial.println("]");

first=false;

}

//display log line

void mainDisplay() {

Serial.print("Avg T.int [");

Serial.print(tempInt);

Serial.print("], Avg T.ext [");

Serial.print(tempExt);

Serial.print("], Avg Tdiff [");

Serial.print(tempDiff);

Serial.print("], Command [");

Serial.print(command);

Serial.print("], RPM [");

Serial.print(getFanSpeed());

Serial.println("]");

}

//display temp measurements before avg processing

void curTempDisplay(double tInt, double tExt) {

Serial.print("T.int [");

Serial.print(tInt);

Serial.print("], T.ext [");

Serial.print(tExt);

Serial.println("]");

}

void loop()

{

if(first) {

header();

}

//this loop is a trick to get a more stable temp, under +5v LM35 is quite unprecise...

double avgInt = 0;

double avgExt = 0;

for(int i=0; i < avgLoop; i++) {

double tInt = getTempInt();

double tExt = getTempExt();

avgInt += tInt;

avgExt += tExt;

curTempDisplay(tInt, tExt);

delay(1000);

}

//calculate setpoint (tempDiff)

tempInt = avgInt / avgLoop;

tempExt = avgExt / avgLoop;

tempDiff = tempInt - tempExt;

if(tempDiff < 0) {

tempDiff = 0;

}

//process PID

myPID.Compute();

//apply PID processed command

analogWrite(fanControl, command);

//display log

mainDisplay();

}Monitoring

It’s possible to visualize debug output using Arduino software Serial Monitor, screen or tail.

screen /dev/ttyACM0 9600tail -f /dev/ttyACM0Links

Hardware.fr tests of 63 120mm fans (fr)

Hardware.fr tests of Coolink SWIF2 (fr)